3 methods of minimizing energy losses in certified transformers

In a previous article, we depicted the economic benefits that the end user has from installing and using certified low voltage transformers, in comparison with the non-certified transformers; we also used a specific example for the installation of ten (10) transformers 0.5kVA each to demonstrate the benefits.

Based on that, the annual benefit from purchasing a certified transformer (in comparison with a non-certified one) was 111€; also, the depreciation of its price difference (due to its higher purchasing cost) will be done in less than six (6) months.

In this article, we present three main methods of minimizing energy losses during the designing and installation of certified transformers.

1. Using a highly specialized software

EMMIS is using one of the most advanced and sophisticated software for designing its transformers, in contrast with “empirical” methods that are commonly in the markets today and by no means can they reach the levels of accuracy and reliability of a highly specialized software.

The use of advanced software in the designing process enables the manufacturer to proceed with testings, alternative calculations and corresponding adaptations to the end product before it enters the production line. This way, all parameters and possible combinations are tested and necessary adaptations are done. The result is the identification of the optimal production strategy ensuring minimum energy losses.

It is worth mentioning that similar advanced softwares are used from the largest companies in the sector such us Legrand, Siemens etc.

2. Special air-vents

Energy losses are directly linked to the temperature of the transformer during its operation.

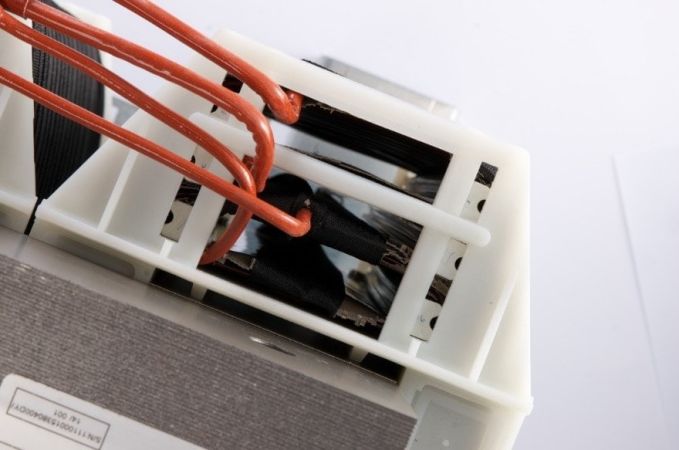

Low thermal losses – which are part of the overall energy losses – are achieved by manufacturing and applying special vents between the coils, allowing the unimpeded heat dissipation.

For this purpose, it is necessary to apply innovative winding technics following modern production methods.

3. Minimizing iron losses

Besides thermal losses, it is possible to further minimize energy losses through minimizing iron losses (no load).

Minimizing iron losses can be achieved through the use of steel sheet core of very low losses.

Therefore, the selection of good quality steel sheet core directly affects the energy losses and the operational cost of the transformer.

Suppliers of core should be selected after careful consideration of the technical data in order to ensure the minimization of its losses. Steel sheet core must also bring the necessary certification.